Pressed metal make a great option for a kitchen splashback. The panels are large – 1830mm long and either 610 or 915mm high. You cut them to fit (see below) and then glue them to the wall with Soudal High Tack Fix All Adhesive. Trim off any exposed edges with an aluminium or timber capping and then silicone across the bench top and under cupboards.

Powdercoated panels are easy to clean with warm soapy water or a microfibre cleaning cloth. Just wipe down and you are done!. No more messy stained grout to deal with.

WHAT ARE THE PANELS MADE OF?

Period Details proudly supply Australian made ‘Pressed Tin Panels’. These panels are made from 0.55mm mill grade Aluminium sheets, they will not rust and are suitable for both interior and exterior use. Although the panels are only 0.55mm thick they do become quite rigid once the pressing process occurs.

HOW MANY PANELS WILL YOU NEED?

Bring in, text or email us a plan of your kitchen and photos. Don’t stress, the plan can just be a quick sketch. Period Details staff just need to see the layout of your kitchen together with measurements. From this they will calculate the number of panels you require and advise on suitable trims for finishing off exposed edges. With over 30 years’ experience in supplying and installing Pressed Metal our staff can provide you with design ideas and the most economical layout.

WHICH PATTERN SHOULD YOU CHOOSE?

Chat to our sales staff to determine the best pattern and finish for your kitchen splashback.

The 152mm x 152mm (or less) pattern repeats work well in any kitchen. On heights of 750mm or more, larger pattern repeats can be used.

Suggested designs are:

- Acorn

- Brick

- Carnivale

- Carousel

- Clover

- Evans

- Fish Scale

- Lachlan Hearts

- Large Maple

- Lily

- Lizards

- Maze

- Melbourne

- Mudgee

- Original

- Posy

- Savannah

- Snowflakes

- Spades

- Stars

- Wall Panel

RAW, PAINTED OR POWDERCOATED

After pressing ‘Pressed Tin Panels’ are dipped in a non-chromate solution making them ready to polish, paint or powdercoat.

In the raw (silver) finish surface scratches will be present. This is part of the manufacturing process. You can leave the panels raw – we cannot guarantee that they will not stain –but have received positive feedback from past clients.

Panels can be powdercoated, sprayed, brushed or rolled to achieve the desired coverage.

For ease of cleaning in a kitchen we have found powdercoating to be a wonderful solution. Powdercoating is paint in a powder form with resin added. It is sprayed onto the sheets and then baked in a large commercial oven. We use Joton, Interpon and Dulux Powdercoat products. The only time we have had powdercoating chip was when we applied powdercoat over an already powdercoated surface.

Powdercoated ‘Pressed Tin Panels’ are easy to keep clean with warm soapy water or warm water and Methylated Spirits. Use with a soft ‘lint free’ cloth or a Micro-fibre cloth. Simply wipe over the area regularly and it will look great for years to come.

Please note: Detergents that recommend the use of gloves when handling must not be used as this is a good indication that the detergent is harsh and therefore, unsuitable for cleaning powder coated pressed metal surface.

If painting check with your paint supplier to see if there is a paint that is suitable for kitchen splashbacks. Apply an “All in One” Primer/Sealer/Undercoat e.g. Dulux 1 step and then top coat. Check with you paint supplier to ensure the Undercoat and Top Coat are compatible.

If leaving in the “raw” aluminium finish. You can leave as is or use a metal polish such as “metasol” or “autosol” to polish out the scratches that are part of the manufacturing process (scratches are covered by the paint or powdercoat)

KITCHEN SPLASHBACK: INSTALLATION INSTRUCTIONS

BEFORE YOU BEGIN: WE SUGGEST THAT YOU READ THROUGH THE INSTRUCTIONS

Tools that may be required:

- Tape Measure and a Builders Pencil

- Straight Edge

- Stanley Knife and spare blades for the Stanley Knife

- Tin Snips – curved (right and left handed)

- Angle Grinder with aluminium cutting disc

- Drill and Hole Saw, Tin Snips and Pliers for cutting GPO holes

- Blue Masking Tape

- Soft Cloth

- Soudal Fix All High Tack Glue – 1 tube per panel for 915 mm sheets and 2 tubes per every 3 610mm panels. Add 1 extra tube per 5 of the 915mm panels.

- Roberts Maxisil “N” Silicon to match panel colour (as close as possible).

- Drop Saw for cutting the Wallboard cappping, timber or 10mm aluminium trim

CAUTION SHOULD BE USED AT ALL TIMES AS METAL EDGES CAN BE VERY SHARP.

- Power Points: for your safety it is best to have an electrician disconnect the power points.

- Gas Cooktops only: If you have less than a 200mm distance between the gas burner and a plasterboard wall, install fire rated sheet (behind cooktop up to 450mm high)

STEP 1: WIPE DOWN THE WALL

- Ensure the wall surface is smooth and clean from any loose debris and dust. Wipe over with a damp soft ‘lint free’ cloth.

STEP 2: MEASURING AND LAYING OUT THE PATTERN

- Measure the wall where the splashback will be installed.

- Determine how you will set out the pattern to minimise joins.

- Don’t join behind or near your cooktop as this is the area of the splashback that will be wiped down the most.

- Center the first panel to the cooktop and then work to the left and right (if applicable).

Ask yourself these questions:

- Which direction will you have the overlap in?

- Which is the prominent way you look at the splashback?

- Where is the light source?

- Remember all panels are pressed to allow a 7mm (approximately) overlap join on every edge.

Don’t forget that the patterns are directional:

- Our ‘Pressed Tin Panels’ have a sticker on the back showing the direction in which they have come off the press – make sure that these stickers all run the same way – this will provide you with much neater overlaps.

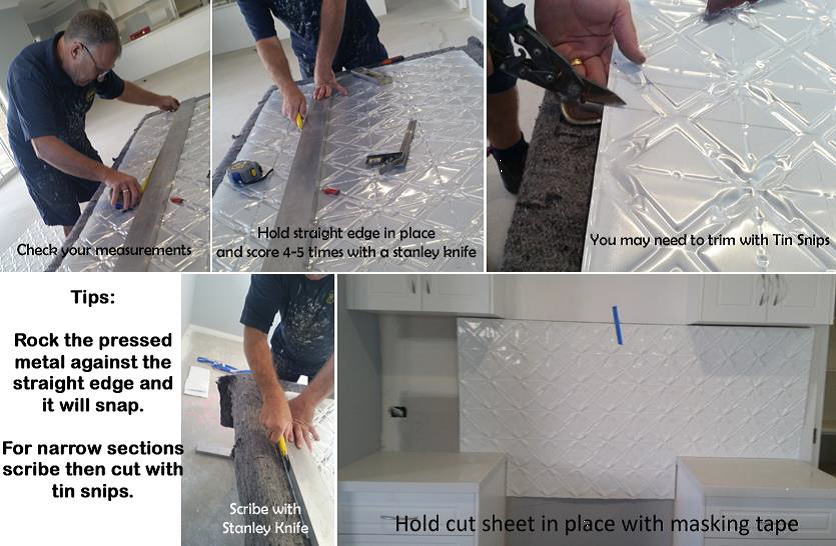

STEP 3: CUTTING THE PANELS

Measure and cut the first panel.

- Lay the panel face down (sticker is on the back) on a stable work table covered in an old clean rug/blanket – we use felt underlay.

- Measure and scribe the panel where it is to be cut.

- Use a straight edge and a Stanley knife. Score 4-5 times then rock against the straight edge and the metal will snap.

- Take over to the splashback area and check that it fits.

- If the panel needs to be adjusted, measure and scribe again.

- If it is a narrow area to be cut start by using tin snips, always cut away from the powdercoated surface. The strip may tear off or you may need to cut the whole length with tin snips.

- Scroll down to see details on cutting out GPO’s (power points).

- Hold sheet in place on the wall with Blue Masking Tape to check that it fits neatly. You can use this as a guide when measuring the area for the next panel.

Second and subsequent panels.

- Measure where the next panel is to be installed (remember to allow for overlaps)

- Cut and fit the next panel.

- Scroll down to see details on cutting out GPO’s (power points).

- Hold panel(s) in place on the wall with Blue Masking Tape and work your way around the room.

Corners:

If possible fold corners as opposed to joining in the corner. This will depend on the pattern profile.

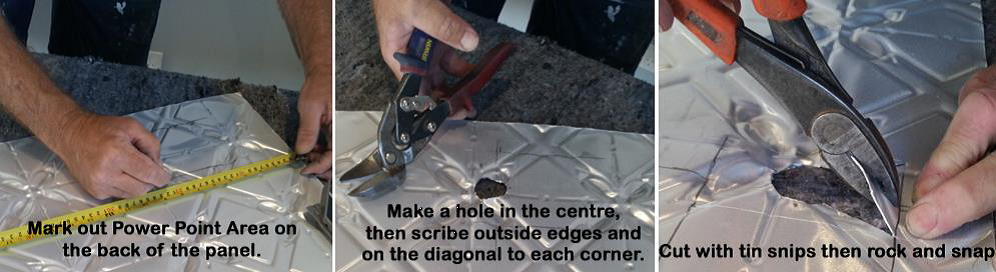

Power Points:

- Mark the position of the power point on the back of the panel.

- Using a straight edge scribe a 90 x 55mm rectangle.

- Scribe diagonally to each corner.

- Drill a hole in the centre point with the hole saw.

- Use the tin snips to cut along the diagonal scribed lines to the outer corners.

- The metal can then be rocked back and forth and it will snap at the outside scribe lines.

STEP 4: ATTACH THE PANELS TO THE WALL.

- Once you have pre-cut and check fitted all the panels remove from the wall and set aside in the order that they will be installed.

- Remember the direction of your overlaps.

- Lay the first panel face down on your clean work surface.

- Starting in a corner, cover the back of the sheet with ‘Soudal Fix All High Tack’ on flat surfaces.

- Be generous. Use a whole tube on the 1837 x 925mm panels.

- Run a bead of ‘Soudal Fix All High Tack’ down the wall approximately 25mm in from each end.

- Place the panel on the wall into position.

- Rub over with a soft cloth (Tip: Remove all jewellery) to ensure a bond between the metal and the wall.

- Continue for the remaining panels.

STEP 5: SILICONE : Where the sheets overlap and between bench top and base of the pressed metal splashback.

- To minimise the appearance of the overlap, using the blue masking tape mask the edges of both panels at the overlap. Silicone along this edge. Remove excess silicone and then remove the tape.

- Run a bead of Robert Maxisil “N” silicone along the top of the bench top and the base of the pressed metal splashback to ensure a water tight seal.

- Run a bead of silicon where the splashback meets overhead cupboards, window frames, door frames etc.

- For a neat finish always remove excess silicone.

Exposed Edges

If your splashback has exposed edges we recommend finishing them off with either Wallboard Capping, 10mm aluminium trim or timber trim.

Option 1: Fitting Wallboard Capping/10mm Aluminium Trim

- Check fit the Aluminium Capping/Trim – we cut the mitre corners but allow extra length so that the capping/trim can be cut to the exact size on site.

- Cut to size with a drop saw (wrap Blue Masking Tape around the trim to protect the powdercoated surface).

- Run a bead of Robert Maxisil “N” silicone along the back.

- Mount on wall flush to the top edge of the pressed metal splashback.

- Hold in place with Blue Making Tape.

- The Blue Masking Tape can be removed in 24 hours.

Or

Option 2 : Fitting Timber Trim

- Cut timber trim to size.

- Mitre corners for a neater fit.

- Run a bead of ‘Soudal Fix All High Tack’ along the back.

- Mount on wall flush to the top edge of the pressed metal splashback.

- Rub over with a soft cloth.

- Nail to wall at studs (if required).

All instructions are given as a guide only. We hold no responsibility for the incorrect installation or use of our products.

NEED FURTHER ASSISTANCE?

Visit our showroom (Trade Only During Stage 4 Lockdown):

Open Monday to Friday 10am to 4pm.

Phone our showroom:

Phone: 03 9729 1498 or 0405 460 997

Phone our installer:

David Peake on 0418 342 930 (10am-4pm Monday to Friday). Send him a text asking him to call you back if he doesn’t answer.